The machining subcontracting specialist

Specialized in machining and assembly for more than 50 years, we are recognized as experts in the machining of small and medium size parts, in short and medium production run.

Thanks to a high-performance industrial park of 80 machines, the parts are machined on multispindle machining centers and robotized milling, turning and electroerosion.

Spécialisés dans l’usinage et l’assemblage depuis plus de 50 ans, nous sommes reconnus comme experts en usinage de pièces de petites et moyennes dimensions, en petite et moyenne séries.

Grâce à un parc industriel performant de 80 machines, les pièces sont usinées sur des centres d’usinage multibroches et robotisés en fraisage, tournage et électroérosion.

The industrial park

8 5-axis palletized centers

3 5-axis centers

4 3-axis centers

2 large size centers

1 twin spindle lathes 3 turrets

1 twin spindle lathes 2 turrets

5 twin spindle lathes 4-axis

5 4-axis lathes

6 2-axis lathes

1 integrex

4 turning machines

4 electro-erosion machines

2 surface grinding machines

2 large-size milling machines

1 CN milling machine

4 Tri Di machines (control)

2 large-size milling machines (foam and wood machining)

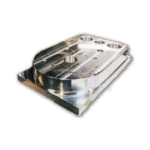

The Mori-Seiki 5-axis palletized machine park allows the machining of complex parts at the best cost.

Programming

- Programs established from 3D files provided by customers or the Design Office

- Possible conversion of Catia, SolidWorks, Creo2 et Pro-Ing files into STP

- Programming, creation of a technical file locking the tools and their functions, the isostatic position, the program and any specific comment necessary.

Material cutting

- Cutting done on site

- Traceability assured on our ERP SAP By Design

- Identification of the material with a batch number

Competitiveness

- Management focused on customer satisfaction

- Robotic machines

- 5-axis machines reducing the number of operations

- Precise machines for quality

- An efficient industrialization department that collaborates with customers to optimize the design and cost of parts

- A quality assurance system connected to continuous improvement

- An efficient IT tool to manage forecasts and capacity

![BV_Certification_ISO9001-EN9100 [Converti] BV_Certification_ISO9001-EN9100 [Converti]](https://www.arkania-group.com/wp-content/uploads/elementor/thumbs/BV_Certification_ISO9001-EN9100-Converti-q18h2i9zsog6zm9z3qz3d0y8946l397bfv97rwb7gc.png)